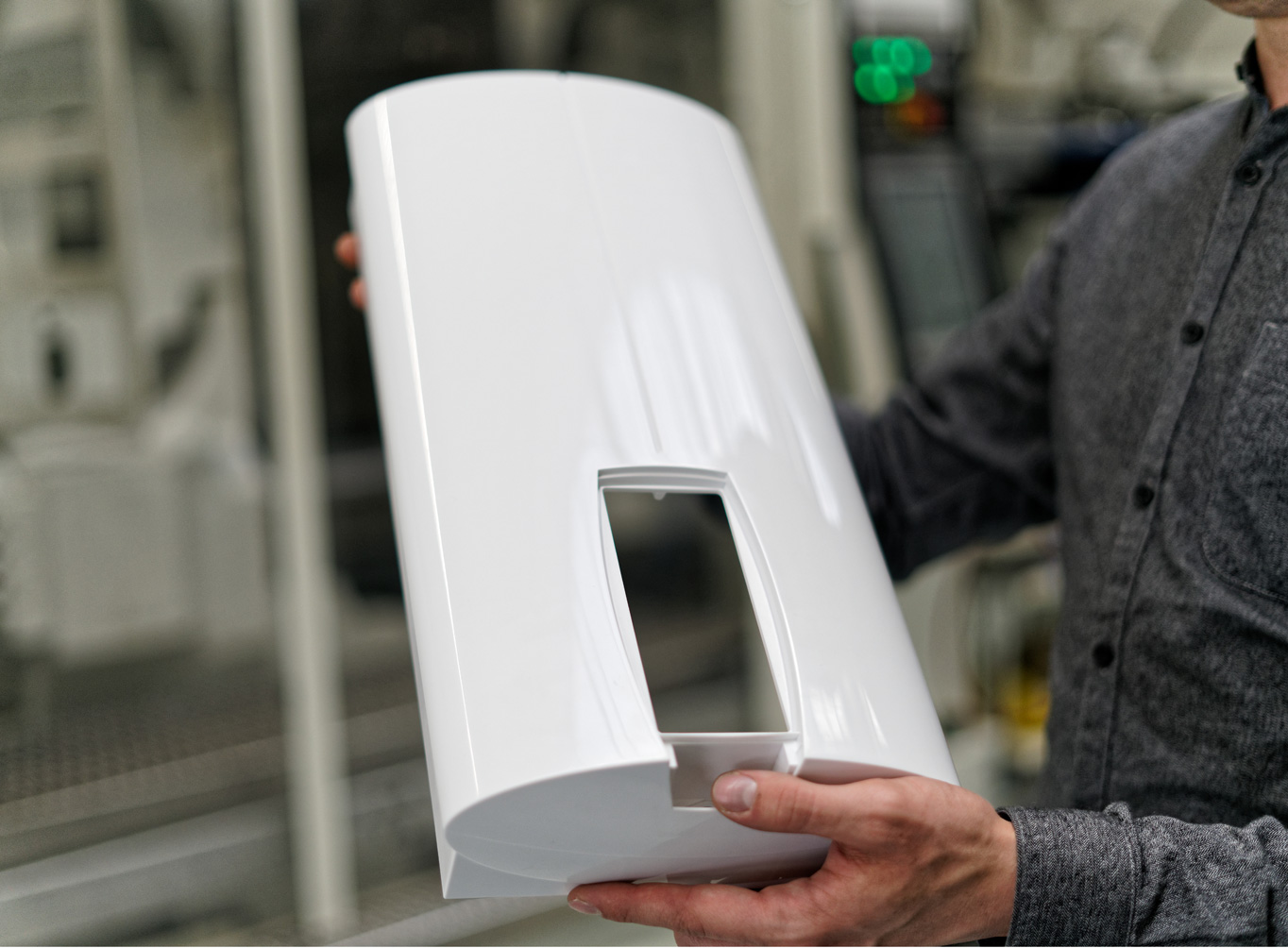

Visible Parts

- The implementation of optical technologies requires a high-quality machine, tool and process technology, as well as a clean production environment.

- The smallest component defect such as a speck, streak or flow line leads to immediate rejection. This can be reduced to a minimum by our extensive know-how on the product, process and production. The definition of the process-relevant parameters with their tolerance limits, as well as the permanent quality control of the optical products, is of immense importance.

- The process parameters time, pressure, speed and temperature determine the intensity and the course of the shear effects and the cooling effects on the plastic melt, from which the quality characteristics such as shrinkage, internal stress and surface defects result.